Bucking Unit

Continuously rotate 360° bucking unit is a special machine widely used in oil fields and industrial enterprises for assembling and disassembling threaded connections of oil casings and other downhole tools.

Both the master tongs and back-up tongs are clamped by hydraulic cylinders, featuring reliable clamping performance. It can achieve non marking clamping, ultra-short distance clamping, and eccentric clamping.

The master tongs can continuously rotate 360° for any number of turns. The back-up tongs are equipped with a left-right movement device.

The hydraulic control device provides power for the active drive. The motor drives pump. High-pressure oil passes through the multi-way valve, which is used to control the forward rotation (reverse rotation), clamping (loosening) of the master tongs, the clamping(loosening) and left-right movement of the back-up tongs respectively.

There are thre pressure-regulating handwheels on the control panel for easy pressure adjustment. It can also be controlled by an electric remote control handle and is equipped with PLC.

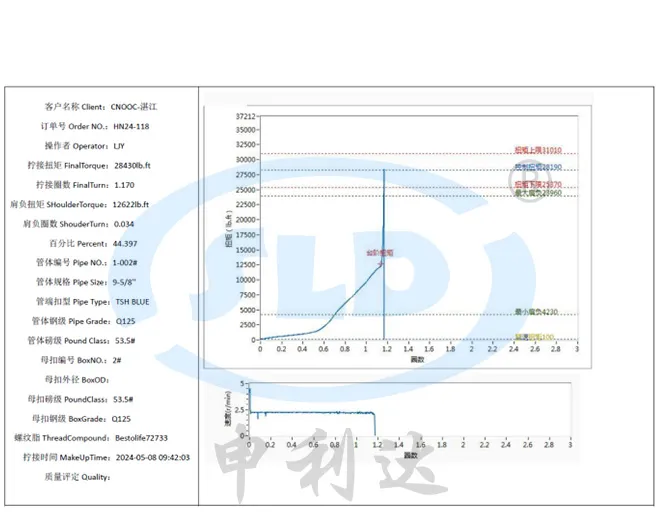

Equipped with an automatic torque control system: After setting the torque value, the sensor under the back-up tongs measures the signal. After computer processing, it automatically generates curves of turns-torque, time-torque, and rotation speed-time. When the torque reaches the set value during make-up, the relief valve automatically unloads, and the equipment stops rotating. The make-up and break-out torque can be measured. The interface can be freely switched between Chinese and English, and the units can be freely switched between kilonewton-meters and foot-pounds.

It has the function of automatic deceleration when the torque approaches the set value.

The bucking unit is a non - standard product and can be customized.

Device Config

| Item | Name | Remarks |

| 1 | Bucking Unit | Standard Configuration |

| 2 | Hydraulic System | Standard Configuration |

| 3 | Torque Automatic Control System | Standard Configuration |

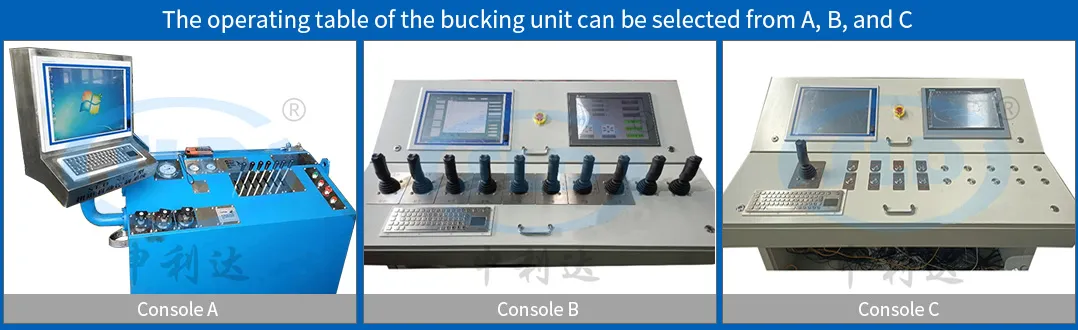

| 4 | The Console | Standard Manual Operation, Optional Electronic Control Operation |

| 5 | One Foot Pedal | Standard Manual Operation, Optional Electronic Control Operation |

| 6 | Feed Rail (R)、Feed Rail (L) | |

| 7 | Hydraulic Support Stand(R)(L) | |

| 8 | With An Eccentric Device | |

| 9 | With An Ultra-Short Distance Clamping Device | |

| 10 | No-Mark Function | |

| 11 | Back-Up Tongs Opening Function | |

| 12 | Pull/Push Device |

Jiangsu Shenlidada Machinery Manufacturing Co., Ltd.'s bucking nuit was featured on China Central Television on January 3, 2016 (CNOOC)

Application Scenarios

| Model | SLD 4 ½-25 | SLD 5 ½-25 | SLD7 ⅝-25 | SLD 9 ⅝-40 | SLD 10-70 | SLD 10-136 | SLD 13-70 | |

| Size Range |

60~114.3mm (23/8~4 ½") |

60~139.7mm (2 3/8~5 ½") |

60~195mm (2 3/8~7 ⅝") |

60~244.5mm (2 3/8~9 ⅝") |

60~254mm (2 3/8-10") |

60~254mm (23/8-10") |

60~339.7mm (2 3/8-13 3/8") |

|

| Rated Pressure | MPa | ≥16 | ||||||

| PSI | ≥2320 | |||||||

| Working Flow | L/min | 80~120 | 80~120 | 80~160 | 80~160 | 80~160 | 80~160 | 80~160 |

| Max. Torque | KN.m | 25 | 25 | 25 | 40 | 70 | 136 | 70 |

| Kft.lbs | 18.45 | 18.45 | 18.45 | 29.52 | 51.66 | 100 | 51.66 | |

| Speed | RPM | 0~10 | 0~6 | 0~6 | 0~6 | 0~6 | 0~6 | 0~6 |

| Model | SLD14-150 | SLD14-180 | |

| Size Range | 60~355.6 mm | ||

| (2 3/8~14") | |||

| Max. Pressure | MPa | ≥16 | |

| PSI | ≥2320 | ||

| Rated Pressure | MPa | 16 | |

| PSI | 2320 | ||

| Working Flow | L/min | 120~230 | |

| Max. Torque | KN.m | 150 | 180 |

| Kft.lbs | 110.7 | 132.84 | |

| Speed | RPM | 0~6 | 0~6 |

|

Model |

SLD18-70 |

SLD18-160 |

SLD18-210 |

SLD18-250 |

SLD20-70 |

SLD20-110 |

SLD 22-160 | |

|

Size Range |

60~457.2mm (23/8~18") |

60~550mm (23/8~20") |

60~558.8mm (23/8~22") |

|||||

|

Rated Pressure |

MPa |

≥16 |

||||||

|

PSI |

≥2320 |

|||||||

|

Working Flow |

L/min |

120~230 |

||||||

|

Max. Torque |

KN.m |

70 |

160 |

210 |

250 |

70 |

110 |

160 |

|

Kft.lbs |

51.66 |

118.08 |

154.98 |

183.82 |

51.66 |

81.18 |

118.08 | |

|

Speed |

RPM |

0~10 |

0~6 |

0~6 |

0~6 |

0~6 |

0~6 |

0~6 |

| Model | SLD24-70 | SLD24-96 | SLD24-140 | SLD24-160 | SLD24-210 | SLD24-260 | |

| Size Range | 60~615mm | ||||||

| (23/8~24") | |||||||

| Rated Pressure | MPa | ≥16 | |||||

| PSI | ≥2320 | ||||||

| Working Flow | L/min | 120~230 | |||||

| Max. Torque | KN.m | 70 | 96 | 140 | 160 | 210 | 260 |

| Kft.lbs | 51.66 | 70.848 | 103.32 | 118.08 | 154.98 | 191.88 | |

| Speed | RPM | 0~7 | 0~8 | 0~12 | 0~7 | 0~5 | 0~5 |

Jiangsu Shenlida Machinery Manufacturing Co., Ltd. was founded in 2002 and is located at No. 46, Jianyang Industrial Central Zone, Jianhu County, Yancheng City, Jiangsu Province. It focuses on and deeply explores the petroleum machinery field.

The company has the independent right to import and export, and its products sell well both at home and abroad. The SLD bucking unit has been recognized and used by the world's three major oilfield service companies---Schlumberger, Baker Hughes, Weatherford company.

Shenlida is a specialized, refined, characteristic, and new small - and medium - sized enterprise in Jiangsu Province and a network member unit of Sinopec, CNPC, and CNOOC. The company has passed the ISO 9001 quality management system, ISO 14001 environmental management system, and GB/T 28001 occupational health and safety management system certifications, effectively guaranteeing product quality and enterprise operation.

The company's products cover petroleum drilling and production equipment as well as automated equipment for drilling and workover operations, including various tubing tongs, casing tongs, drill pipe tongs, an intelligent torque automatic control system,bucking unit and supporting equipment, meeting diverse operation scenarios. The products are not only widely used in major domestic oilfields but also exported to regions such as Europe, America, Southeast Asia, the Middle East, and the Commonwealth of Independent States.

The company attaches great importance to R & D and innovation. It has set up a petroleum machinery research department and obtained 12 national invention patents. Meanwhile, it actively conducts industry - university - research cooperation with universities and undertakes scientific research projects of CNPC and CNOOC, contributing to the technological upgrading of the industry.

Adhering to the concept of "Quality - oriented, Innovation - driven", Shenlida is committed to providing global customers with environmentally friendly and intelligent petroleum machinery solutions. We warmly welcome domestic and foreign merchants to negotiate cooperation and create a bright future for the petroleum machinery industry!

Português

Português