Common faults and troubleshooting methods during the use of Bucking Unit

Browse services

- Petroleum and Gas

- What are the advantages of using a Bucking Unit?

- Common Bucking Unit Operation Errors and How to Avoid Them?

- What are the safety checks before operating a Bucking Unit?

- Bucking Unit Safety Operating Procedures

- How to Use the Operator Panel to Control a Bucking Unit

- How to Calibrate a Bucking Unit?

- What preparations are needed before using the Bucking Unit?

- What is the operating procedure of the Bucking Unit?

- Common faults and troubleshooting methods during the use of Bucking Unit

- How should I replace worn parts of the Bucking Unit?

- How to maintain the electronic control system of the Bucking Unit?

- How does Bucking Unit handle oil leaks?

09 Aug

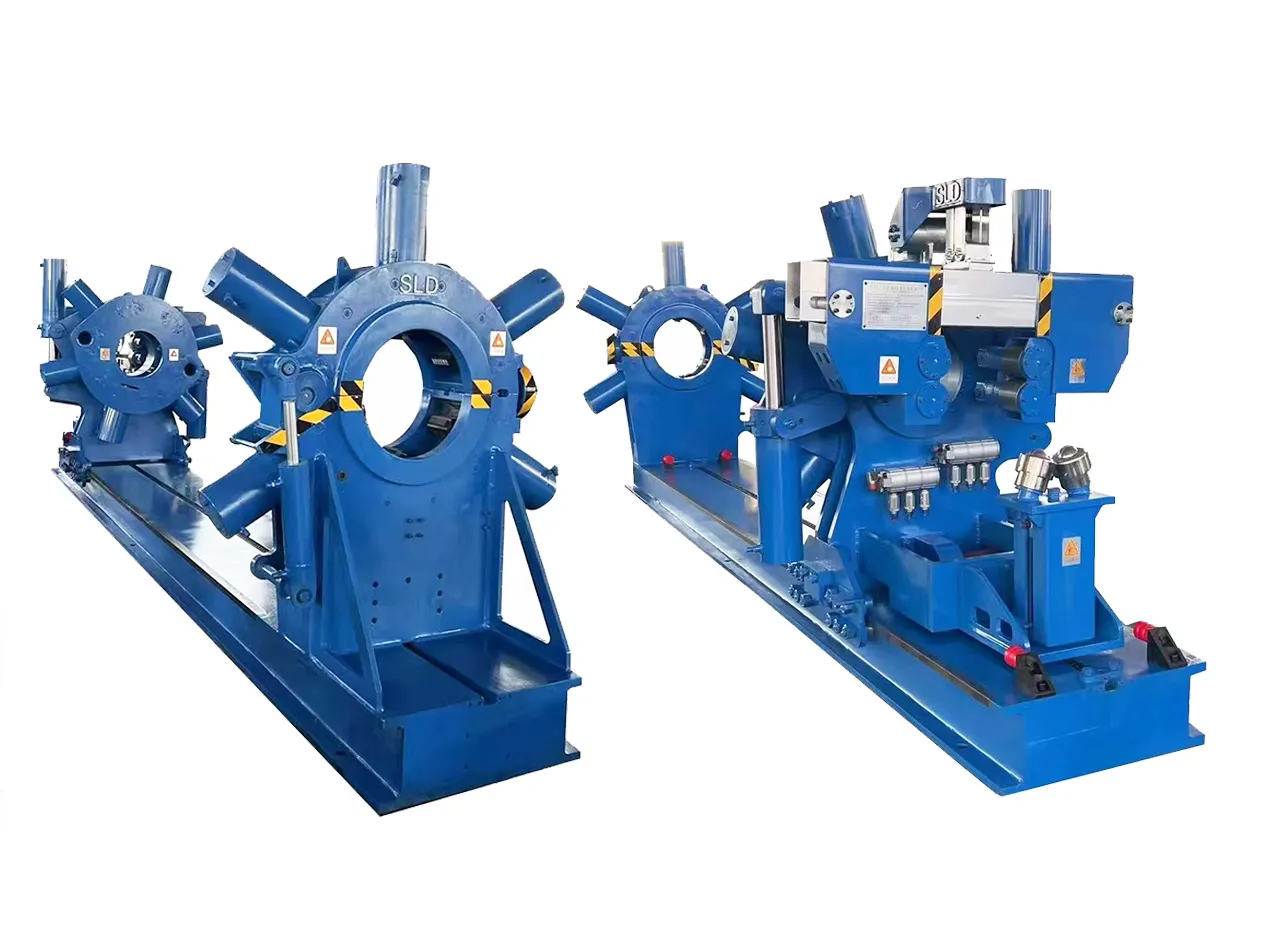

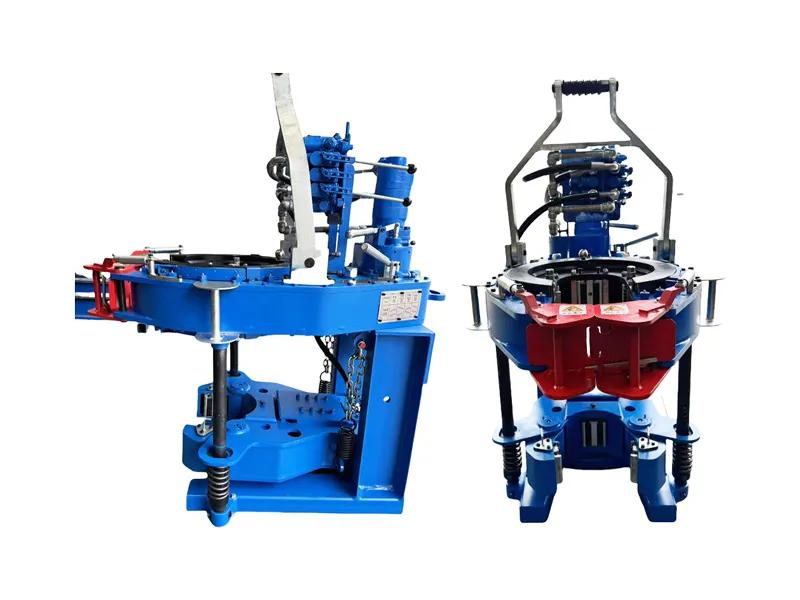

Bucking units play a critical role in drilling operations in industries such as oil and gas, primarily used to connect and disconnect drill pipe, tubing, and casing. Due to the complex operating environment and heavy loads, bucking units can experience various malfunctions during use. Promptly and accurately identifying and troubleshooting the cause of the malfunction is crucial to ensuring safe and stable operation of the equipment. The following describes common types of malfunctions during bucking unit use and their troubleshooting methods.

1. Hydraulic System Failures and Troubleshooting

The hydraulic system is the power source of the bucking unit, and malfunctions are common and have significant impacts.

Common Failures:

Insufficient hydraulic pressure

This may manifest as slow or incomplete actuator movement.

Excessive hydraulic oil temperature

Can cause hydraulic oil deterioration and accelerate component wear.

Hydraulic oil leakage

Leaks

Can result in insufficient pressure and oil loss.

Abnormal noise or vibration from the hydraulic pump

Impact system stability.

Troubleshooting Methods:

Check the hydraulic oil level and quality to confirm that it is sufficient and free of contamination.

Check the oil filter for blockage and replace or clean the filter element promptly. Check the hydraulic lines and joints for leaks, damage, or looseness.

Test the hydraulic pump pressure output to determine if it is normal.

Monitor the oil temperature to confirm that the cooling system is functioning properly.

Observe the operating status of the hydraulic cylinder and valve assembly to eliminate internal leaks.

2. Electrical Control System Faults and Troubleshooting

The electronic control system is responsible for the operation and data feedback of the Bucking Unit. Failures can affect operational efficiency and safety.

Common Faults:

No response from the operating panel or abnormal signals

Loss or errors in sensor signals

PLC control program abnormalities or freezes

Poor contact in cables or connectors

Troubleshooting Methods:

Check the control cabinet power supply for normal operation and fuses for blown fuses.

Test the response of the panel buttons and touch screen to ensure normal sensitivity.

Use testing equipment to read sensor signals and confirm the integrity of the sensors and wiring.

Check the tightness of all terminals and connectors to prevent looseness and oxidation.

Restart the PLC system to check if normal operation is restored. If necessary, restore the program backup.

Monitor software alarm information and use the fault code to locate the fault.

3. Mechanical Structure Failures and Troubleshooting

The mechanical structure carries out the equipment's clamping and torque transmission functions, and its failures often affect connection quality.

Common Failures:

Unstable or slipping jaws

Abnormal spindle rotation or binding

Guide rail wear leading to uneven slide movement

Loose or broken fastening bolts

Troubleshooting Method:

Check the jaw gaskets for severe wear and replace them promptly.

Confirm that the jaw clamping force meets the set value to eliminate any possible clamping failure.

Check the spindle bearing lubrication and any abnormal noise. Add lubricant or replace the bearings if necessary.

Inspect the guide rail and slide surfaces for scratches or rust, and maintain lubrication.

Regularly check for loose key fasteners and tighten or replace them promptly.

4. Safety Device Failures and Troubleshooting

Safety devices are crucial for ensuring operator safety and the normal operation of the equipment.

Common Failures:

Malfunctioning emergency stop button

Malfunctioning limit switch

Ineffective over-torque protection

Troubleshooting Method:

Press the emergency stop button to test whether the equipment stops immediately. Check the limit switch installation position and circuit continuity to ensure sensitive operation.

Test the over-torque protection device by simulating an overload condition to verify proper triggering.

Troubleshoot the safety system circuits individually to prevent open circuits or short circuits.

5. Faults Caused by Improper Operation and Troubleshooting

Some faults are not inherent to the equipment but rather result from improper operation.

Common Symptoms:

Poor connection quality

Abnormal equipment startup or frequent alarms

Troubleshooting Methods:

Verify that the operating procedures comply with the equipment operating procedures and ensure that each step is performed according to standards.

Check that the torque setting is appropriate to avoid overtightening or undertightening.

Provide operator skills training to improve equipment proficiency.

Review equipment operation records, analyze the cause of the alarm, and provide guidance on corrective actions.

6. Comprehensive Troubleshooting Recommendations

In actual maintenance, faults are often not caused by a single factor. A systematic approach should be adopted when troubleshooting:

Approach the problem from easy to difficult, from the outside in: First check for obvious external issues, then delve into internal components. Combine equipment operating status and alarm information: Use fault codes provided by the intelligent control system to assist in diagnosis.

Maintain good records and follow-up: After each troubleshooting and repair, record the cause of the fault and the corrective action to facilitate subsequent analysis.

Regular maintenance and servicing: Preventing faults is the most effective measure.

Conclusion

Bucking units can experience a variety of faults during operation, including those in the hydraulic, electrical, mechanical, and safety systems. Understanding and mastering common faults and their troubleshooting methods can improve troubleshooting efficiency, reduce equipment downtime, and ensure operational safety and production continuity. A combination of standardized operation, regular maintenance, and timely troubleshooting is the foundation for the long-term, stable operation of the bucking unit.

Português

Português

.webp)