What preparations are needed before using the Bucking Unit?

Browse services

- Petroleum and Gas

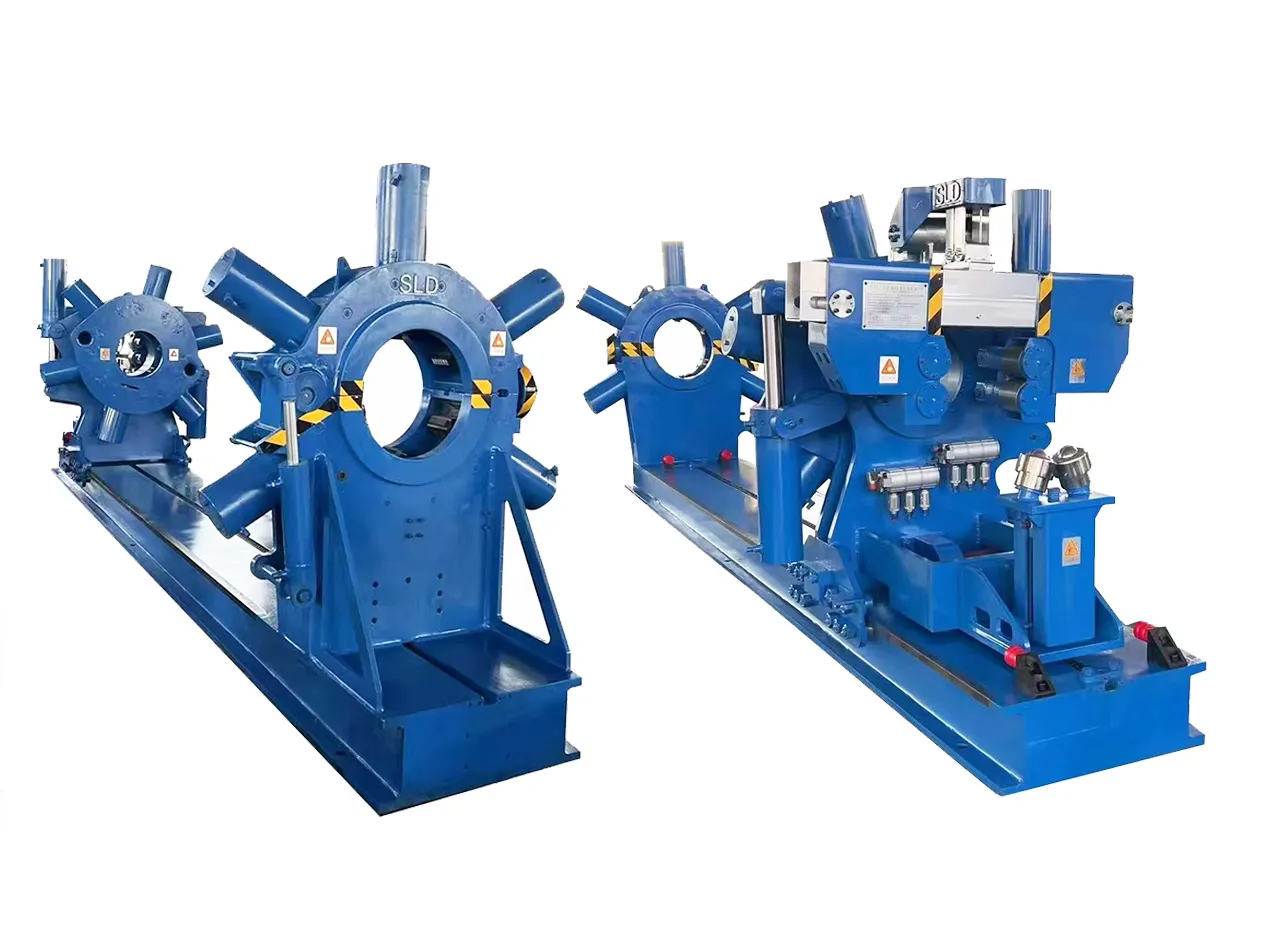

- Jiangsu Shenlida Machinery Manufacturing Co., Ltd. made its debut at the Abu Dhabi Petroleum Exhibition

- What are the advantages of using a Bucking Unit?

- Common Bucking Unit Operation Errors and How to Avoid Them?

- What are the safety checks before operating a Bucking Unit?

- Bucking Unit Safety Operating Procedures

- How to Use the Operator Panel to Control a Bucking Unit

- How to Calibrate a Bucking Unit?

- What preparations are needed before using the Bucking Unit?

- What is the operating procedure of the Bucking Unit?

- Common faults and troubleshooting methods during the use of Bucking Unit

- How should I replace worn parts of the Bucking Unit?

- How to maintain the electronic control system of the Bucking Unit?

12 Aug

Preparing the Bucking Unit (screwdriver) before use is crucial for ensuring safe and efficient operation. Thorough preparation not only prevents equipment failures and accidents, but also ensures the safety of operators and improves overall efficiency. The following details the necessary preparatory work for the Bucking Unit, covering four aspects: equipment inspection, operating environment, personnel preparation, and related procedures.

1. Equipment Inspection

Appearance and Mechanical Inspection

Before operation, carefully inspect the Bucking Unit's mechanical structure to ensure there are no obvious deformations, cracks, or loose parts. Specifically, check the jaws, clamping mechanism, spindle, and drive system for integrity. Ensure lubricated areas are adequately lubricated to prevent wear caused by dry friction.

Hydraulic System Inspection

The hydraulic system is the primary power source for the Bucking Unit. Ensure the hydraulic oil level is normal and clean. Inspect the hydraulic oil tank, pipe connections, and joints for leaks. Ensure the filter element is clean and unobstructed, and that the hydraulic pump is running smoothly and without abnormal noise.

Electrical Control System Inspection

Confirm that the control cabinet and operating panel are intact and that all indicators and displays are functioning properly. Check that the emergency stop button is responsive and effective. Cable terminals must be secure and not loose to prevent electrical failures during operation.

Safety Device Inspection

Confirm that the equipment's protective devices, such as limit switches, protective covers, and safety fences, are intact and effective. Ensure that all safety devices are functioning properly and can quickly stop the equipment in an emergency.

2. Work Environment Preparation

Site Cleanliness and Safety

Ensure that the Bucking Unit installation site is flat and solid, free of accumulated water, oil, and debris to prevent slips and equipment instability. The work area should be demarcated with safety zones and warning signs to prohibit non-operating personnel from entering.

Lighting and Ventilation

Ensure adequate lighting at the work site to facilitate observation of equipment operating conditions. Good ventilation helps remove oil vapor and dust, reduce fire hazards, and protect the health of operators.

Preparing Auxiliary Equipment

Check that the lifting equipment, handling tools, and support devices are in good condition and capable of meeting operational requirements. Arrange the work area appropriately to facilitate the flow of materials and personnel.

3. Personnel Preparation

Operator Qualifications

Operators operating the Bucking Unit must undergo systematic training, be familiar with the equipment's performance, operating procedures, and safety regulations, and hold the appropriate operator's certificate. Untrained personnel are prohibited from operating the equipment.

Personal Protective Equipment

Operators must wear a hard hat, protective gloves, protective shoes, and work clothes. Goggles and earmuffs, if necessary, should be worn to protect against mechanical splash and noise.

Clear Job Responsibilities

The operation team must clearly define their duties and designate specific individuals responsible for equipment operation, auxiliary handling, and safety monitoring to ensure coordination and enhance operational efficiency and safety.

Safety Education and Emergency Drills

Regular safety training and emergency drills should be conducted to enhance operators' ability to respond to emergencies. Operators must be familiar with the emergency stop device and accident handling procedures.

4. Pre-Operation Procedure Verification

Pre-Startup Self-Test

According to the equipment manual, operators must perform a pre-startup self-test, including a hydraulic pressure test, an electrical system self-test, and a mechanical operation test. The equipment may only be started after confirming that there are no abnormalities.

Workpiece Verification

Verify that the specifications of the drill pipe, tubing, or casing to be connected match the equipment specifications to ensure proper functioning of the clamping device. Verify that the workpiece surface is free of oil, rust, and damage.

Torque Parameter Setting

Set the torque parameters of the Bucking Unit according to operational requirements and technical specifications to avoid connection quality issues or equipment damage caused by incorrect parameter settings.

Communication and Coordination

Operators must maintain clear communication with other on-site personnel and clearly communicate command signals to avoid safety hazards caused by misoperation and cross-operation.

Summary

Preparatory work before using the Bucking Unit includes equipment inspection, environmental setup, personnel allocation, and operational procedures. Each step requires meticulous attention and strict adherence to relevant standards and procedures to ensure that the equipment is in good condition, the operating environment is safe, personnel are qualified, and the operational process is scientific and rational. Only in this way can equipment failure rates and the probability of safety accidents be effectively reduced, ensuring the smooth progress of drilling operations.

Português

Português

.webp)