What is the operating procedure of the Bucking Unit?

Browse services

- Petroleum and Gas

- What are the advantages of using a Bucking Unit?

- Common Bucking Unit Operation Errors and How to Avoid Them?

- What are the safety checks before operating a Bucking Unit?

- Bucking Unit Safety Operating Procedures

- How to Use the Operator Panel to Control a Bucking Unit

- How to Calibrate a Bucking Unit?

- What preparations are needed before using the Bucking Unit?

- What is the operating procedure of the Bucking Unit?

- Common faults and troubleshooting methods during the use of Bucking Unit

- How should I replace worn parts of the Bucking Unit?

- How to maintain the electronic control system of the Bucking Unit?

- How does Bucking Unit handle oil leaks?

11 Aug

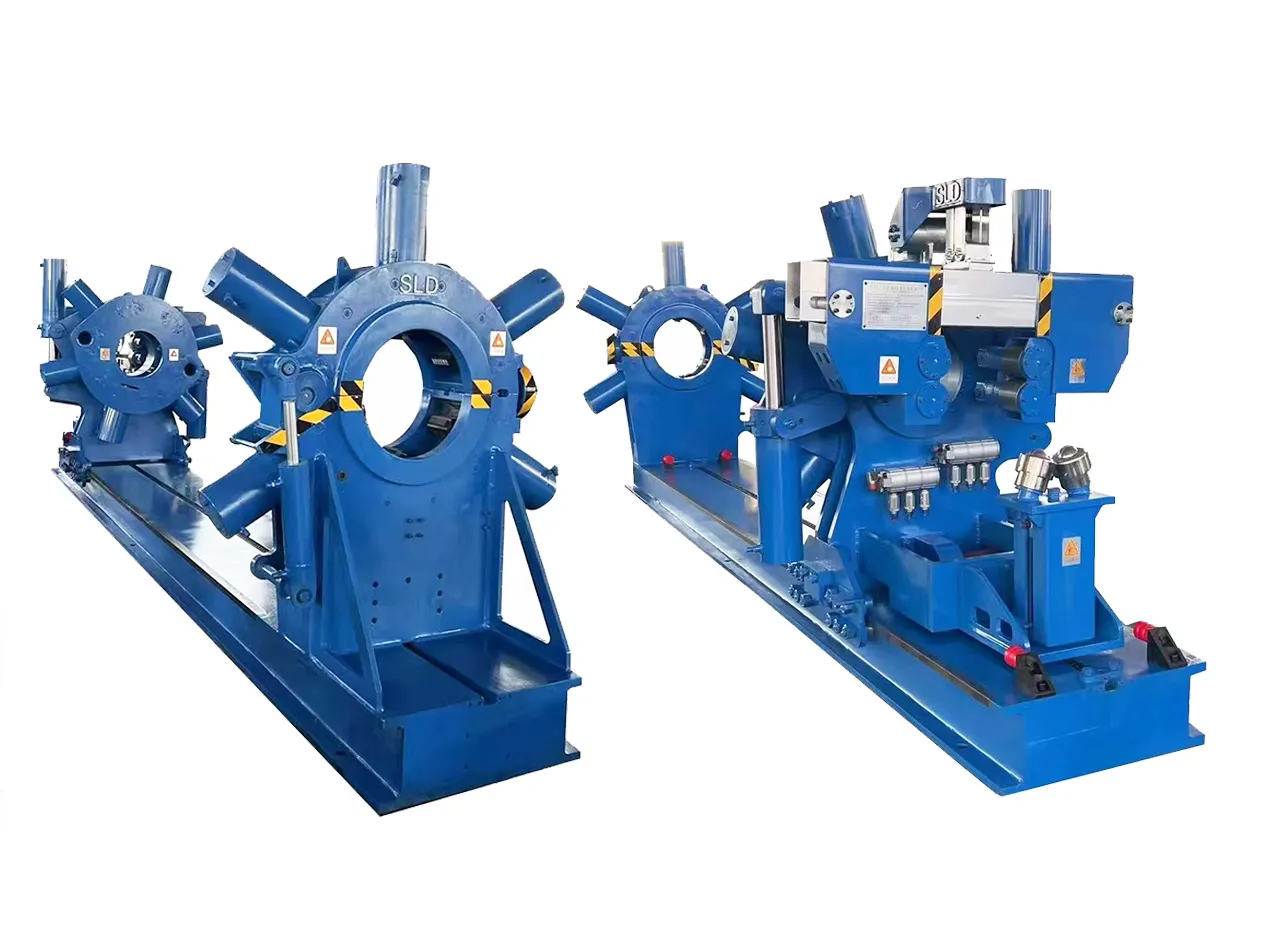

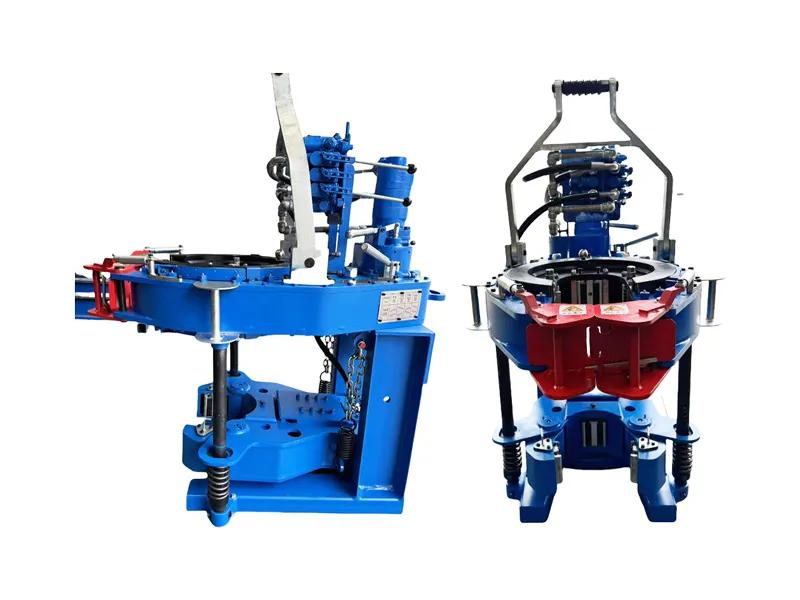

The Bucking Unit (Bucking Unit) is a crucial piece of equipment used to connect and disconnect drill pipe and tubing during drilling operations. The standardization and safety of its operating procedures are directly related to drilling efficiency and personnel safety. Correct operating procedures not only effectively extend the lifespan of the equipment but also prevent mechanical failures and accidents. The following details the standard operating procedures for the Bucking Unit, covering preparation, operating procedures, safety measures, and post-operation inspections.

Pre-Operation Preparation

Personnel Preparation

Operators must undergo specialized training and be familiar with the Bucking Unit's structure, performance, and operating procedures to ensure they possess the appropriate operating qualifications. They must also wear appropriate labor protection equipment, including a hard hat, protective gloves, protective shoes, and overalls.

Equipment Inspection

Perform a comprehensive inspection of the Bucking Unit before operation. Specifically, check that the hydraulic system is functioning properly, that the oil level is sufficient, and that there are no leaks; that the electronic control system indicators and operating panel are functioning properly; that mechanical parts are free of looseness, obvious damage, and are properly lubricated. Ensure that the emergency stop button and safety limiters are functioning properly.

Work Environment Verification

Confirm that the work site floor is level and clean. Ensure that there are no debris or obstructions around the equipment that could interfere with operation. Safety warning signs should be posted in the work area to prevent unauthorized personnel from entering.

Standard Operating Procedures

Equipment Startup

According to the startup procedures, turn on the electrical control system and hydraulic system, slowly apply pressure, and ensure that the equipment is in a no-load, ready state. The operator should confirm that the control panel is functioning normally and that there are no alarms or faults.

Docking and Positioning

Using auxiliary equipment (such as a lift), accurately align the drill pipe, tubing, or casing to be connected to the clamping area of the Bucking Unit. Operators should maintain a safe distance to prevent accidents during operation.

Clamping and Fixing

Control the jaw clamping device using the operation panel to ensure a secure grip on the workpiece. The clamping force should meet the equipment's set requirements to avoid workpiece slippage or damage due to excessive clamping.

Torque Setting

Enter or adjust torque parameters in the control system based on the connection requirements. Proper torque settings ensure connection quality and prevent overtightening that may damage the workpiece, or undertightening that may affect connection strength.

Tightening Operation

Start the torque drive system and perform the tightening operation according to the pre-set program. The equipment automatically monitors the torque value and adjusts it, stopping automatically when the set torque is reached. Operators should closely monitor the operation process and stop immediately if any abnormality is detected.

Disassembly Operation

After connection is complete, if disassembly is required, first adjust the torque setting to the appropriate range to ensure safe disassembly. Loosen the jaws using the control panel and slowly release the pressure to ensure smooth separation of the workpiece.

Safety Verification

After each operation, confirm that the clamping device is fully released and the equipment is unloaded. Only then can the operator move out of the work area and prepare for the next operation.

Key Points for Safe Operation

Overloading is strictly prohibited.

When operating the equipment, the design parameters must be adhered to. Overloading is strictly prohibited to prevent mechanical damage or safety accidents.

Maintaining Concentration

Maintaining full attention during operation, avoid distraction or impulsive operation, and ensure accurate movements.

Adhere to Emergency Stop Procedures

If an abnormal situation or equipment alarm occurs, immediately press the emergency stop button to cut off power. Only address the problem after confirming it is safe.

Keep Humans Out of Dangerous Areas

While the equipment is operating, operators and auxiliary personnel must not enter the clamping area or near moving parts to prevent pinching or collision accidents. Perform regular equipment maintenance.

Strictly adhere to the equipment maintenance plan to maintain the equipment in good condition and reduce the risk of failure.

Post-Operation Inspection and Cleaning

Equipment Status Verification

After operation, conduct a comprehensive inspection of the Bucking Unit to confirm that hydraulic pressure has returned to normal and that there is no abnormal wear or looseness in the mechanical parts.

Clean the Work Site

Clean up oil and debris around the equipment and maintain a clean work environment to prevent slips and fire hazards.

Record Operation Information

Detailed records of operation time, workpiece specifications, torque parameters, and abnormalities will be kept to provide data support for equipment management and subsequent maintenance.

Problem Feedback and Resolution

Promptly report any equipment abnormalities or operational issues to the maintenance department for professional inspection and rectification.

Summary

The Bucking Unit operation process involves multiple steps, encompassing both technical operations and safety management. Standardized operating procedures can effectively improve equipment efficiency, ensure connection quality, and maximize personnel safety. Operators must strictly adhere to operating procedures, perform pre-startup preparatory checks, follow the procedures for clamping, tightening, and disassembly, closely monitor equipment status during operation, and promptly respond to any abnormalities. After the operation is completed, equipment maintenance and site cleanup are performed to prepare for the next operation. Only through scientific and standardized operating procedures can the Bucking Unit achieve maximum efficiency and ensure smooth drilling operations.

Português

Português

.webp)