What are the advantages of using a Bucking Unit?

Browse services

- Petroleum and Gas

- What are the advantages of using a Bucking Unit?

- Common Bucking Unit Operation Errors and How to Avoid Them?

- What are the safety checks before operating a Bucking Unit?

- Bucking Unit Safety Operating Procedures

- How to Use the Operator Panel to Control a Bucking Unit

- How to Calibrate a Bucking Unit?

- What preparations are needed before using the Bucking Unit?

- What is the operating procedure of the Bucking Unit?

- Common faults and troubleshooting methods during the use of Bucking Unit

- How should I replace worn parts of the Bucking Unit?

- How to maintain the electronic control system of the Bucking Unit?

- How does Bucking Unit handle oil leaks?

26 Aug

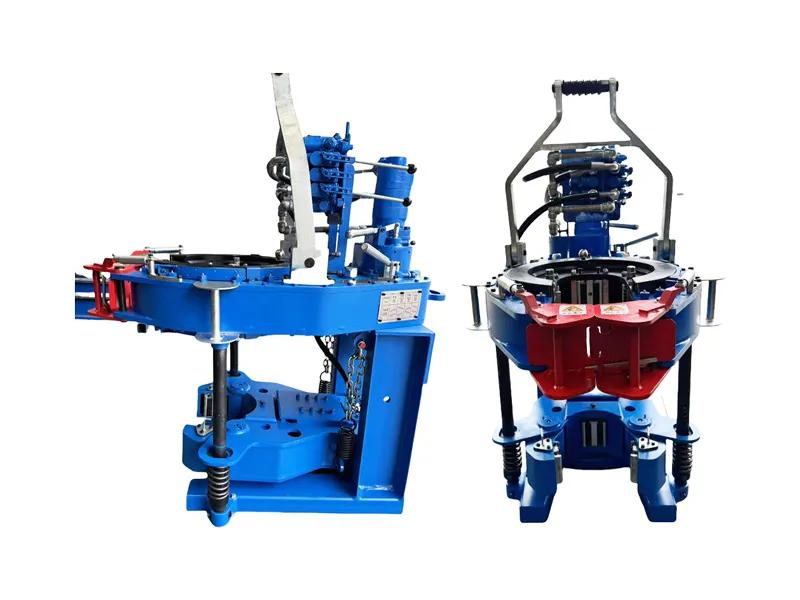

As modern industry demands ever-increasing product quality and production efficiency, the Bucking Unit, as a key torque control device, is widely used in various fastening processes. Its precise torque output and efficient automation significantly address the shortcomings of traditional fastening processes, making it a crucial tool for improving production quality and ensuring safety. This article will detail the multiple advantages of using the Bucking Unit to help you understand its irreplaceable role in industrial production.

Ensuring Precision in Fastening Quality

The Bucking Unit's core advantage lies in its precise control of tightening torque. Using advanced sensors and control systems, the device accurately detects and adjusts torque values, ensuring that each fastener meets the predetermined torque standard.

Avoiding Under- or Over-Tightening

Traditional manual or mechanical fastening often results in uneven force, leading to loose connections or component damage. The Bucking Unit, through digital control, achieves standardized and consistent torque, significantly reducing rework and failures caused by substandard fastening quality.

Improving Product Consistency and Reliability

Precisely achieving the set torque value at each fastening point ensures overall product structural stability, reduces quality risks caused by poor connections, and extends product lifespan and safety.

Improving Production Efficiency and Automation

The Bucking Unit, combined with automated control technology, enables efficient and continuous tightening operations, significantly improving production line efficiency.

Shortening Tightening Time

Automatic torque control and quick-action design significantly reduce tightening cycles, making it particularly suitable for high-volume production.

Reducing Dependence on Human Resources

The equipment automatically completes the tightening process, reducing operator physical burden and operational complexity, while also lowering the risk of human error.

Integrating Production Lines to Achieve Intelligence

By connecting to a host computer or production management system, the Bucking Unit enables real-time data collection and remote monitoring, promoting intelligent and digital production processes.

Improving Operational Safety

Safety is fully considered in the Bucking Unit design to ensure operator and equipment safety.

Equipped with Safety Guards

Rotating components are equipped with protective covers to prevent injury from contact with moving parts. Safety gates and interlocks ensure the equipment cannot be started unless protective measures are in place.

Emergency Stop System

The emergency stop button and multiple alarm systems promptly respond to abnormal conditions, quickly shutting off power to the equipment and preventing accidents from escalating. Reduce safety hazards caused by human error. Standardized operating procedures and automated control systems reduce the risk of operator error and ensure a safe working environment.

Adapting to Diverse Production Needs

The Bucking Unit offers high flexibility and adjustability, suitable for a variety of tightening scenarios.

Various Specifications and Torque Ranges

The unit can adjust the torque range to suit different product specifications and process requirements, meeting diverse requirements from light loads to high-strength tightening.

Compatible with Different Fastener Types

It is compatible with a variety of bolts, nuts, and connectors and is widely used in industries such as automotive manufacturing, mechanical assembly, and electronic equipment.

Easy Integration with Other Equipment

It can seamlessly integrate with conveyor lines, robots, and inspection equipment, achieving efficient collaboration within automated production lines.

Data Monitoring and Quality Tracking Advantages

The Hyundai Bucking Unit is equipped with comprehensive data collection and management capabilities, providing strong support for quality control and production management.

Real-time Data Collection

Records information such as torque value, time, and operator for each tightening, ensuring process traceability.

Quality Statistical Analysis

Data analysis enables timely identification of abnormal tightening conditions, optimization of process parameters, and reduction of defective product rates. Supports integration with production management systems.

Upload data to an MES (Manufacturing Execution System) or ERP system to enable digital management and intelligent decision-making of the production process.

Reduced Maintenance Costs and Extended Equipment Life

Bucking Units are manufactured using high-quality materials and advanced processes, ensuring stable operation and simple maintenance.

High Durability

Precision manufacturing ensures wear resistance and interference resistance of mechanical and electrical components, reducing failure rates.

Easy Maintenance

The equipment is designed for easy maintenance. Regular lubrication and calibration ensure long-term stable operation and reduce maintenance costs.

Reduced Equipment Downtime

High-reliability design reduces equipment downtime and improves production continuity.

Enhanced Competitiveness

By introducing Bucking Units, companies can enhance their core competitiveness in multiple areas:

Improve product quality and consistency, meet market demand for high-quality products, and enhance brand reputation.

Reduce labor costs and improve production efficiency, shorten production cycle times and operating costs, and increase profit margins.

Enhance safety management, reduce safety incidents, protect employee health, and foster a positive corporate image.

Achieving digitalization and intelligentization of production processes lays the foundation for future Industry 4.0 transformation.

Conclusion

Using the Bucking Unit is not only a technological upgrade but also an inevitable choice for companies pursuing high-quality, efficient, and safe production. Its precise torque control, automated and efficient operation, safe and reliable design, and intelligent data management capabilities make it a key component of modern manufacturing.

Português

Português