SLD NC-1 Automatic Torque Control System

SLD NC-1 Automatic Torque Control System

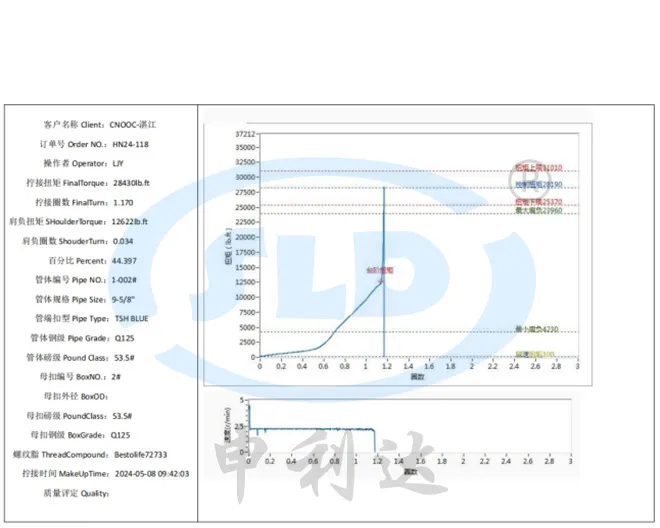

SLD NC-1 Automatic Torque Control System is a highly reliable torque signal processing, control, and recording system. It enables precise measurement, real-time display, data logging, and intelligent control of torque during pipe make-up (threading), ensuring that pipe joints achieve the optimal make-up torque value. The system provides full-process monitoring and data retention for the tightening of each joint, with graphical records (e.g., torque curves) generated during the process stored on a disk for future query and analysis.

The system can be used together with power tong and bucking unit, keeping the torque within the range required by AMERICAN PETROLEUM INSTITUE (API standard). It intends to protect tubing from damaging tubes when torque is out of the range.

Technical Parameter:

Supply Voltage: 480V、380AC

Working Voltage : 220V

Power Consumption: 500W Max

Range of Torque Meter: 0~300kN.m(Select and configure different pressure sensors according to the torque requirements of the overall pliers and bucking unit)

Control Range: Can be set

Check the Accuracy: ≤2.5%

Unloading Discharge: 80L/min

Unloading Response: 20ms

Ambient Temperature: -20_C to +65_C

Ambient Humidity: 10% to 80% R·H (No condensation)

Volume: long600mm*wide500mm*tall300mm

Weight: 80KG

Jiangsu Shenlida Machinery Manufacturing Co., Ltd. was founded in 2002 and is located at No. 46, Jianyang Industrial Central Zone, Jianhu County, Yancheng City, Jiangsu Province. It focuses on and deeply explores the petroleum machinery field.

The company has the independent right to import and export, and its products sell well both at home and abroad. The SLD bucking unit has been recognized and used by the world's three major oilfield service companies---Schlumberger, Baker Hughes, Weatherford company.

Shenlida is a specialized, refined, characteristic, and new small - and medium - sized enterprise in Jiangsu Province and a network member unit of Sinopec, CNPC, and CNOOC. The company has passed the ISO 9001 quality management system, ISO 14001 environmental management system, and GB/T 28001 occupational health and safety management system certifications, effectively guaranteeing product quality and enterprise operation.

The company's products cover petroleum drilling and production equipment as well as automated equipment for drilling and workover operations, including various tubing tongs, casing tongs, drill pipe tongs, an intelligent torque automatic control system,bucking unit and supporting equipment, meeting diverse operation scenarios. The products are not only widely used in major domestic oilfields but also exported to regions such as Europe, America, Southeast Asia, the Middle East, and the Commonwealth of Independent States.

The company attaches great importance to R & D and innovation. It has set up a petroleum machinery research department and obtained 12 national invention patents. Meanwhile, it actively conducts industry - university - research cooperation with universities and undertakes scientific research projects of CNPC and CNOOC, contributing to the technological upgrading of the industry.

Adhering to the concept of "Quality - oriented, Innovation - driven", Shenlida is committed to providing global customers with environmentally friendly and intelligent petroleum machinery solutions. We warmly welcome domestic and foreign merchants to negotiate cooperation and create a bright future for the petroleum machinery industry!

Português

Português

.webp?x-oss-process=image/resize,w_100/quality,q_100)