How does a Bucking Unit work?

Browse services

- Petroleum and Gas

- What are the advantages of using a Bucking Unit?

- Common Bucking Unit Operation Errors and How to Avoid Them?

- What are the safety checks before operating a Bucking Unit?

- Bucking Unit Safety Operating Procedures

- How to Use the Operator Panel to Control a Bucking Unit

- How to Calibrate a Bucking Unit?

- What preparations are needed before using the Bucking Unit?

- What is the operating procedure of the Bucking Unit?

- Common faults and troubleshooting methods during the use of Bucking Unit

- How should I replace worn parts of the Bucking Unit?

- How to maintain the electronic control system of the Bucking Unit?

- How does Bucking Unit handle oil leaks?

02 Aug

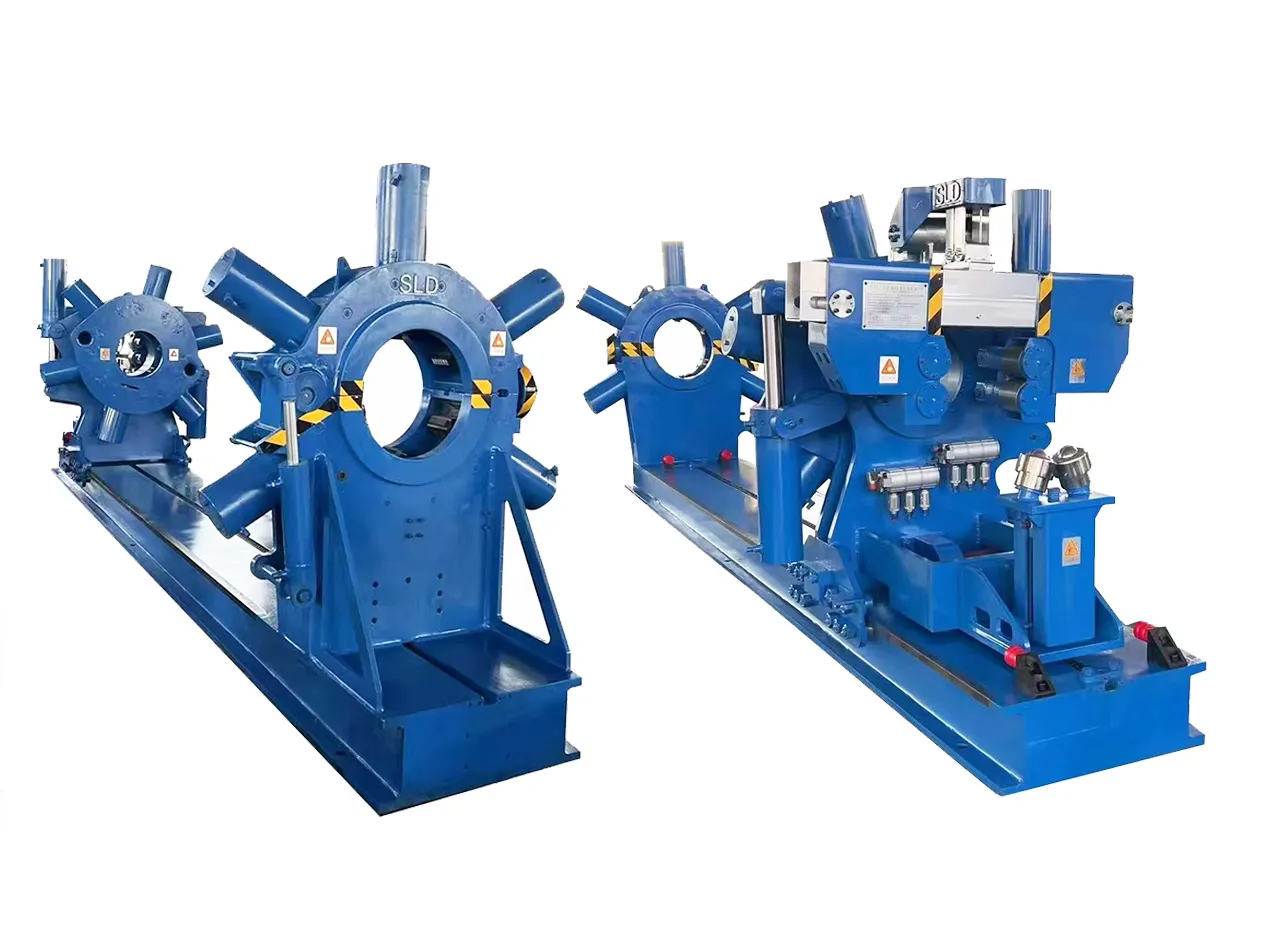

A bucking unit, also known as a thread-unscrewing machine, is a device used for the mechanized assembly and disassembly of threaded connections (such as drill pipe, joints, and tools while drilling). It is particularly critical in energy industries such as oil and gas. Its core task is to complete the "make" (tightening) or "break" (loosening) of connections by precisely controlling torque and rotation angle.

To understand the workings of a bucking unit, we must first examine its structural components, power drive method, control system, and workflow.

1. Main Structure and System Components

Power System

The core of a bucking unit is its drive source, typically a hydraulic motor or electric motor to provide torque output. Hydraulic systems are widely used in industrial equipment due to their smooth output and strong controllability.

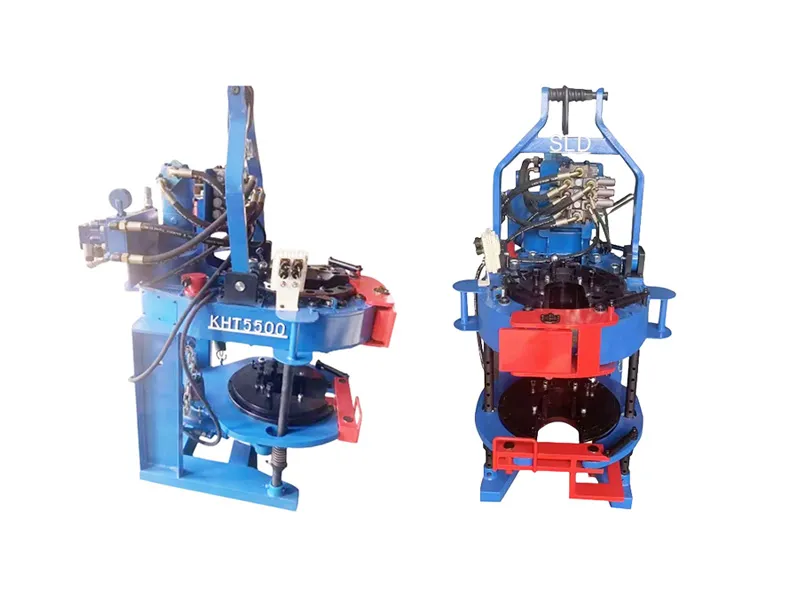

Clamping System

The unit typically features two clamps: a fixed clamp (static clamp) and a movable clamp (movable clamp). The fixed clamp holds one end of the tool in place, while the movable clamp grips the other end and rotates it. The jaws are adjustable to accommodate different tool sizes or pipes. Rotation System

The movable clamp is attached to the rotating mechanism and, using hydraulic or electric drive, rotates forward or reverse to complete connection or removal.

Torque Control System

A sensor monitors the torque output of the device in real time and compares it with the set value. Once the preset torque is reached, the system automatically stops rotation, ensuring precise and consistent connection every time and preventing overtightening or loosening.

Control Interface

The operator sets the required parameters, such as target torque, rotation angle, and rotation direction, using the control panel or touchscreen. Advanced systems may also integrate data acquisition and storage for quality tracking.

2. Workflow Analysis

The basic operating principle of the Bucking Unit can be divided into the following steps:

1. Workpiece Loading and Clamping

The operator places the tool to be connected or removed into the device. The fixed clamp grips one end of the tool, while the movable clamp grips the other. The clamping force is provided by a hydraulic or pneumatic system, ensuring a stable, slip-free clamp.

2. Parameter Setting

The operator enters the target torque value, rotation direction (clockwise for connection, counterclockwise for removal), maximum rotation angle, and other parameters on the control panel. These parameters are typically set according to standards provided by the tool manufacturer to ensure connection quality and safety.

3. Rotation Start

After the device is turned on, the movable clamp, driven by the power system, begins rotating, pushing the tool thread into (or out of) the mating component. Throughout this process, a torque sensor continuously monitors the real-time torque value.

4. Torque Control and Stop

When the rotation reaches the set torque value, the system automatically stops. For assembly operations, this indicates that the thread has been tightened to the design requirement; for disassembly operations, it indicates successful loosening. Some systems also limit the rotation angle to prevent overtightening or damage during disassembly.

5. Data Logging (Optional)

Advanced devices record and store data such as the torque curve, connection angle, and operation time for each operation in the system for quality control, report generation, and traceability.

6. Workpiece Unloading

After rotation is completed, the clamp releases, the operator removes the tool, and the device prepares for the next cycle.

3. Core Principles

1. Torque Control is Key

The core of the Bucking Unit is "precise torque control." Pressurization is applied through a hydraulic or electric motor system, transmitting power to the rotating mechanism, causing the movable clamp to rotate the workpiece. Simultaneously, a torque sensor measures the torque applied to the workpiece in real time and provides feedback to the control system.

Once the set value is reached, the control system immediately responds by stopping rotation, ensuring a secure connection without damaging the threads. This closed-loop control system ensures consistent and repeatable operation from one job to the next.

2. Synchronous Dual Clamp Coordination

The fixed and movable clamps must work in perfect harmony to prevent displacement, slippage, or misalignment during the rotation of the workpiece. The clamps typically feature hardened serrations or a rubber protective coating to ensure clamping force while preventing scratches on the tool surface.

3. Collaborative Hydraulic and Electronic Control

The hydraulic system provides high torque output, while the electronic control system enables precise control of parameters such as torque, time, and angle. Working together, the Bucking Unit combines powerful physical capabilities with a highly intelligent operating experience.

4. Common Control Modes

Manual Mode: The operator controls the start, stop, and clamping process in real time. This mode is suitable for training or small-batch operations. Semi-automatic mode: Clamping is performed manually, while rotation and stopping are automatically controlled by the system based on torque.

Automatic mode: From clamping to rotation, to data recording, the system performs everything, offering high efficiency and minimal error, making it suitable for mass production and high-standard operations.

5. Importance in Practical Applications

In the oil and gas industry, downhole tools are often subjected to torques exceeding thousands of Newton meters and extreme temperatures and pressures. Insecure connections or overtightening can lead to thread damage, tool breakage, or even downhole operation failure. Therefore, using a bucking unit to complete these connections is a key component in ensuring the safety and efficiency of downhole operations.

Furthermore, with the increasing complexity and standardization of tools, manual operations are no longer sufficient to meet the stringent requirements of modern industry, making the use of bucking units increasingly prevalent and important.

Summary

The operating principle of the bucking unit is based on three core elements: the rigid support of the clamping system, the powerful output of the drive system, and the precise feedback of the torque control system. Through synchronous control and closed-loop regulation, it enables reliable assembly and efficient disassembly of tool threaded connections. This type of equipment not only improves connection efficiency but also significantly reduces the risk of human error, making it an indispensable component in heavy industries such as oil, gas, and energy. With technological advancements, Bucking Units are also evolving towards intelligence, automation, and data-driven processes, bringing greater safety and economic benefits to the industry.

Português

Português