How to choose the right Bucking Unit model?

Browse services

- Petroleum and Gas

- What are the advantages of using a Bucking Unit?

- Common Bucking Unit Operation Errors and How to Avoid Them?

- What are the safety checks before operating a Bucking Unit?

- Bucking Unit Safety Operating Procedures

- How to Use the Operator Panel to Control a Bucking Unit

- How to Calibrate a Bucking Unit?

- What preparations are needed before using the Bucking Unit?

- What is the operating procedure of the Bucking Unit?

- Common faults and troubleshooting methods during the use of Bucking Unit

- How should I replace worn parts of the Bucking Unit?

- How to maintain the electronic control system of the Bucking Unit?

- How does Bucking Unit handle oil leaks?

05 Aug

Selecting the appropriate bucking unit model is a crucial step in equipment selection for the oil and gas industry. Bucking units are primarily used to thread and disassemble downhole tools such as drill pipe, tubing, and casing, ensuring reliable connection performance and appropriate preload during downhole operations. Choosing the right model not only impacts operational efficiency but also the lifespan, safety, and economic benefits of the connection. The following are key considerations during the selection process.

1. Identify the Application Conditions and Operational Requirements

First, it's important to fully understand the specific operating conditions in which the bucking unit will be used, including the type of components (e.g., drill pipe, tubing, casing, special tools, etc.), connection dimensions (outer diameter, thread type), and operating environment (onshore or offshore, cold or tropical, open air or in a workshop). Different operating scenarios require different technical parameters, so the model selection should closely reflect actual needs.

For example, if the main application is threading tubing and casing, the equipment needs to support a wide size range and high torque output. If used for drilling tool repair, higher requirements will be placed on repeatability and control systems.

2. Determining Torque Requirements

One of the core performance characteristics of a bucking unit is its output torque capacity. Torque directly affects whether the connector can achieve the designed preload. When selecting a model, consider the recommended torque value for the threaded connection being used and allow for a safety margin to prevent frequent damage to the equipment due to excessive loads.

It is generally recommended that the rated maximum torque of the selected unit be at least 20% greater than the maximum operating torque required by the connector to account for torque fluctuations or abnormal conditions.

3. Compatible Size Range and Jaw Structure

Different bucking unit models support different pipe diameter ranges. Before selecting, clearly define the minimum and maximum outer diameter ranges of the tools to be processed to ensure the unit can reliably grip all target workpieces.

The choice of jaw structure is also crucial. For example, automatically adjustable jaws are suitable for operations involving frequent switching between multiple connector sizes, while traditional mechanical jaws are more suitable for batch operations involving high-strength connections of a single size. Choosing the right jaw structure can improve efficiency and ease of use. 4. Control System and Data Logging

Modern bucking units are often equipped with advanced control systems that achieve closed-loop management of torque and angle control, with data collection, process recording, and quality traceability capabilities. This is particularly important for companies striving for high-standard operational quality management.

When selecting a bucking unit, consider the control system's user-friendly interface, supported languages, data export formats, and support for remote monitoring and diagnostics. Some models also support multi-channel sensor inputs, enabling more precise monitoring of the connection process.

5. Automation and Operational Ease

Choosing the appropriate automation configuration based on the jobsite's staffing and automation needs is crucial. Some bucking units offer one-touch start, automatic centering, and automatic pressurization and depressurization, significantly reducing operator workload and improving operational efficiency.

For high-volume, continuous operations, it is recommended to select models with high automation and rapid changeover capabilities to minimize manual intervention and downtime.

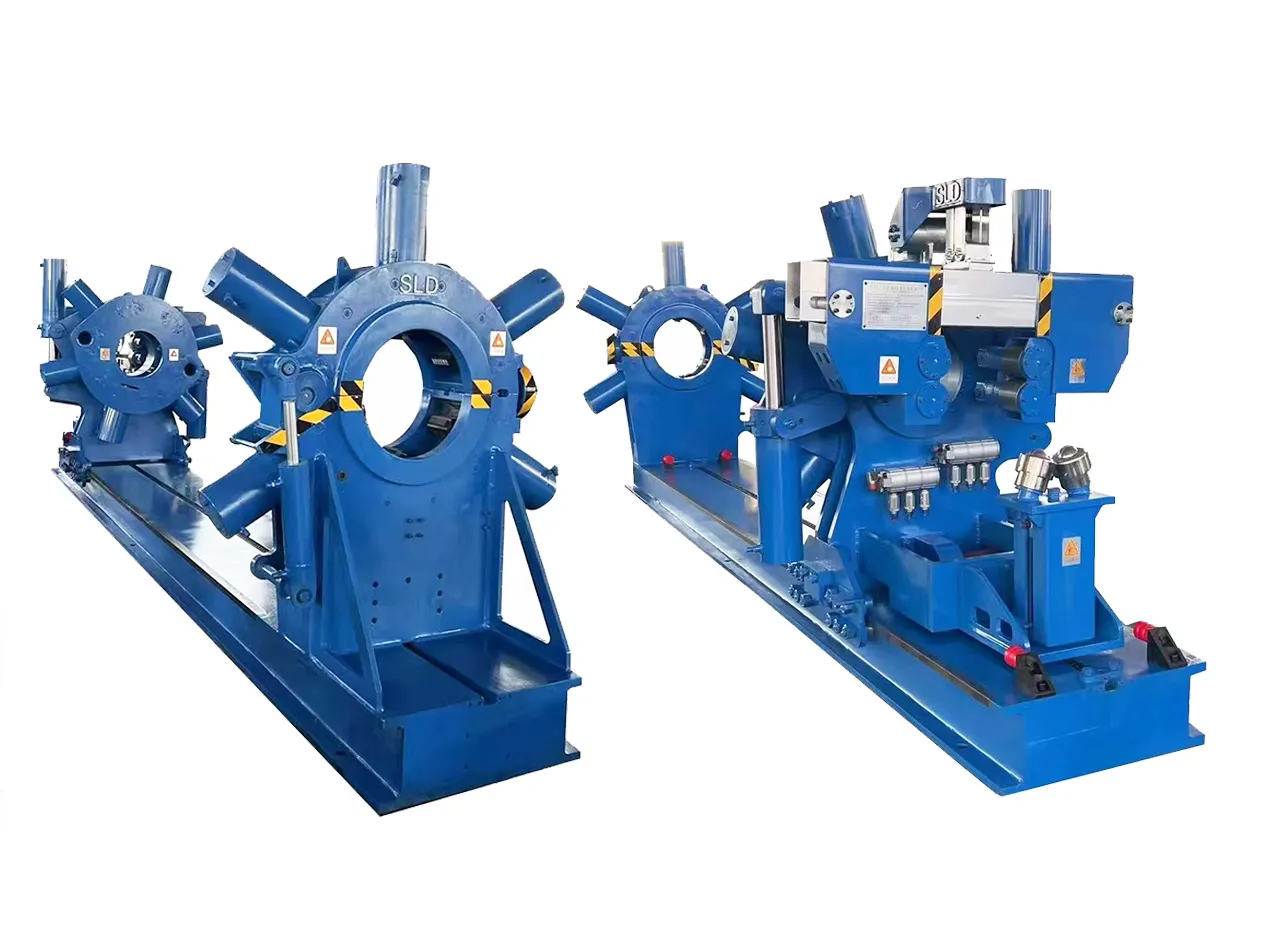

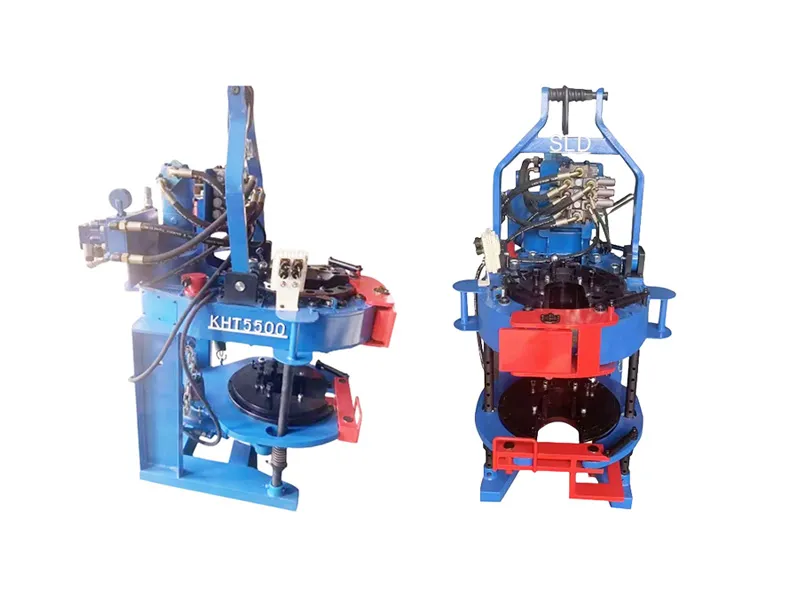

6. Equipment Structure and Installation

Choosing the appropriate equipment structure is also crucial, considering the site's spatial conditions and operational workflow. Common configurations include horizontal, vertical, portable, and vehicle-mounted. If the work site has limited space or requires frequent site changes, a compact, easily movable, and easily installed model is more suitable.

The equipment's installation method must also be tailored to the site conditions. Considerations such as the need for foundation reinforcement, hoisting support, and explosion-proof or dust-proof requirements should all be considered during initial model selection.

7. Maintenance Ease and Reliability

Equipment reliability and ease of maintenance are crucial factors for long-term use. When selecting, consider the compatibility of components, the replacement cycle for wearing parts, the difficulty of routine maintenance, and whether the manufacturer provides comprehensive technical support and spare parts availability.

High-quality bucking units typically feature clear lubrication paths, dust-proof enclosures, and self-protection mechanisms, significantly extending their service life and reducing operating and maintenance costs.

8. Safety Design

Worksite safety is paramount. Equipment should incorporate necessary safety features, such as overload protection, emergency stop devices, workpiece clamping confirmation systems, and anti-incorrect operation features, to ensure operator safety and stable operation. When selecting a model, thoroughly verify the equipment's safety standards and industry regulations, and prioritize models with a strong safety reputation and proven operational experience.

In summary, selecting the appropriate Bucking Unit model requires comprehensive consideration of multiple factors, including operational requirements, workpiece parameters, torque requirements, control system, degree of automation, structural configuration, safety, and ease of maintenance. A scientific selection process not only improves operational efficiency and connection quality, but also reduces operational and maintenance costs, enhances production safety, and improves overall competitiveness. Detailed technical discussions and on-site investigations are recommended during the initial selection phase to ensure the selected model accurately matches the actual application scenario and maximize the return on investment.

Português

Português