What are the common types of Bucking Units?

Browse services

- Petroleum and Gas

- What are the advantages of using a Bucking Unit?

- Common Bucking Unit Operation Errors and How to Avoid Them?

- What are the safety checks before operating a Bucking Unit?

- Bucking Unit Safety Operating Procedures

- How to Use the Operator Panel to Control a Bucking Unit

- How to Calibrate a Bucking Unit?

- What preparations are needed before using the Bucking Unit?

- What is the operating procedure of the Bucking Unit?

- Common faults and troubleshooting methods during the use of Bucking Unit

- How should I replace worn parts of the Bucking Unit?

- How to maintain the electronic control system of the Bucking Unit?

- How does Bucking Unit handle oil leaks?

04 Aug

Bucking units, also known as screwdrivers, are critical equipment used in the oil, gas, geothermal, and mining industries for assembling and disassembling threaded connections (such as drill tools, joints, and tools while drilling). Bucking units are categorized into various types based on operational requirements, working methods, structural design, and degree of automation to suit different scenarios and operational requirements. Understanding the differences between these types is crucial for selecting the appropriate equipment, improving operational efficiency, and ensuring connection quality.

Classification by Drive Method

1. Hydraulically Driven Bucking Unit

This is one of the most common types, using a hydraulic motor as its power source. Hydraulic drive offers advantages such as high torque output, flexible adjustment, and high durability. It is particularly well-suited for heavy-duty connection tasks requiring high torque, such as handling large-diameter drill pipe, heavy-weight drill pipe, or complex tools.

Features:

Stable output, suitable for high-intensity operations

Precise torque control

Requires a hydraulic station and piping system

2. Electric Bucking Unit

Electric motors are the primary power source and are suitable for applications requiring low to medium torque. Electric systems offer fast response, a relatively compact structure, and low maintenance, making them suitable for use in workshops, laboratories, or environments with well-maintained conditions.

Features:

Energy-saving and environmentally friendly

Highly integrated control system

Suitable for connecting and disconnecting small and medium-sized tools

3. Pneumatic Bucking Unit

Powered by compressed air, it is suitable for areas requiring explosion-proofing or where hydraulic or electrical power is limited. Although its torque output is relatively low, its lightweight and easy-to-control features offer unique advantages in certain applications.

Features:

Safe and explosion-proof

Relatively low torque

Suitable for light tools and quick disconnect operations at well sites

Classification by Control Method

1. Manual Control

Starting, clamping, and rotation operations are performed using manual buttons or mechanical valves. Primarily used in repair shops, small-batch production, or training. While the degree of automation is low, its structure is simple and its price is relatively low.

Suitable for applications where equipment is used infrequently or technical requirements are low.

2. Semi-automatic Control

The unit automatically controls the rotation and torque stop points, but manual operation is still required for clamping and loading and unloading workpieces. Combining the efficiency of mechanization with the flexibility of manual labor, it is a common type used by many small and medium-sized enterprises. Advantages: High cost-effectiveness and adaptability.

3. Fully Automatic Control

From clamping and rotation to stopping and data recording, everything is automatically completed by a PLC control system or human-machine interface (HMI). It can be linked with a data acquisition system to achieve fully digital management of the joining process, making it suitable for high-standard, high-volume industrial production processes.

Applications: Automated production lines, tool manufacturers, and large oilfield bases.

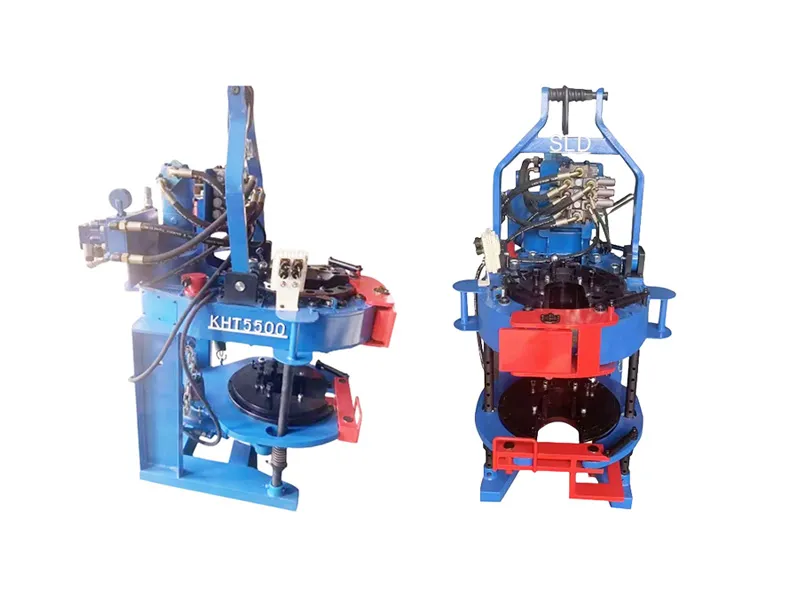

Classification by Clamping Method

1. Chain Clamp Bucking Unit

Clamping is achieved by wrapping a chain around the tool and tightening it. Its simple structure and wide adjustment range make it suitable for various non-standard tool shapes, but it is not suitable for workpieces requiring high surface precision.

Advantages: High versatility and low cost

Disadvantages: Potential scratches on the workpiece surface

2. Clamp Bucking Unit

Using mechanical or hydraulic jaws to directly clamp the tool surface, it offers strong clamping force and high precision. It is widely used in precision joining operations and is suitable for joining high-value, delicate precision tools. Advantages: Stable clamping and workpiece protection.

Disadvantages: Requires changing jaws to accommodate different sizes.

3. V-Bracket Bucking Unit: This unit uses a V-shaped bracket to support the tool and clamps it through pressure. It is suitable for securing slender, complex tools and is particularly effective on small instruments and slender components.

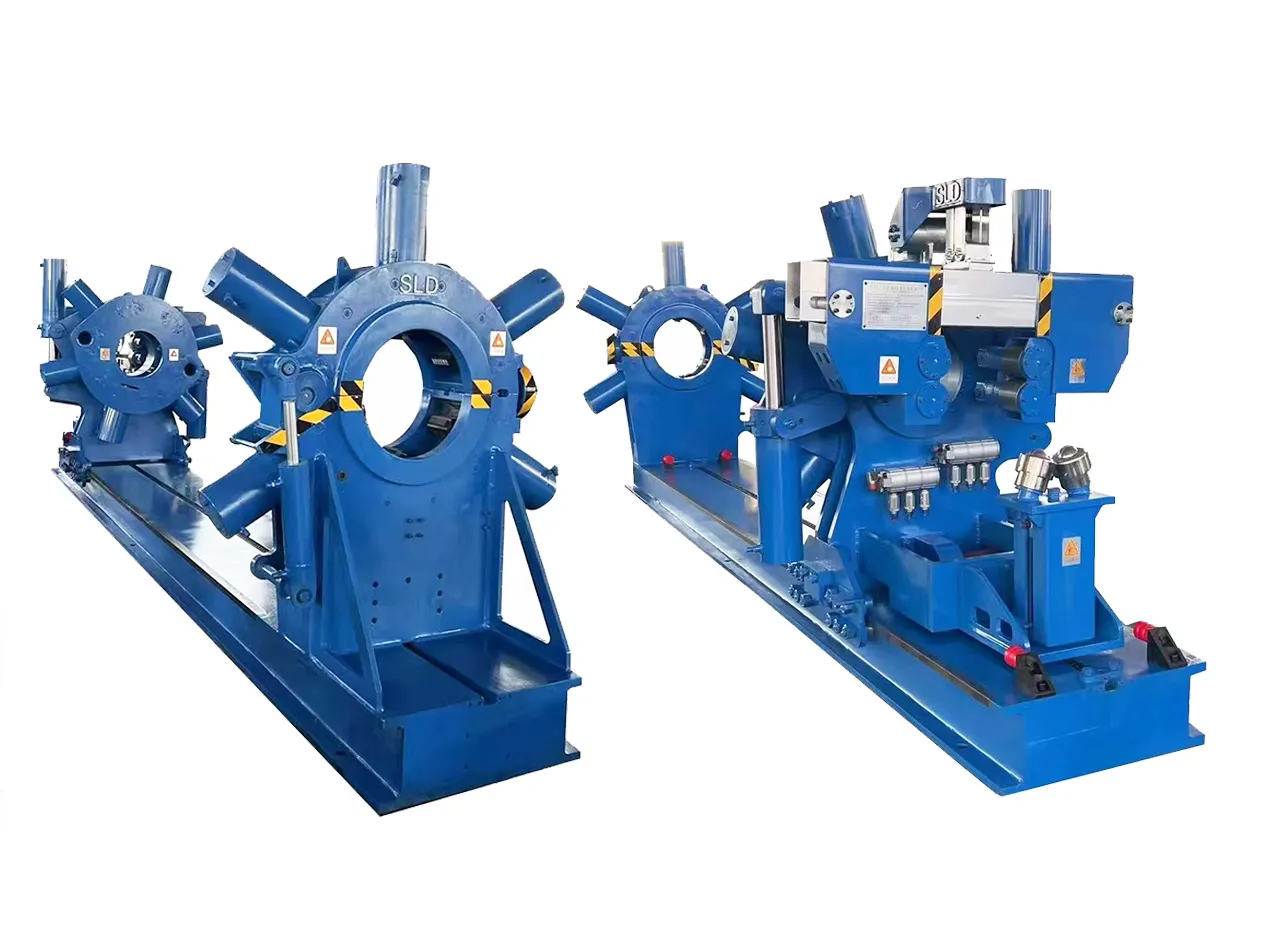

Classification by Installation Method

1. Fixed Bucking Unit: This type is installed on the workshop floor or workbench and is not mobile. It is suitable for fixed work areas or production lines.

Advantages: Good stability and high load capacity.

Disadvantages: Non-mobile and occupies a large space.

2. Mobile Bucking Unit: Typically equipped with rollers or slides, it can be moved to different locations according to operational needs. It is suitable for field, wellsite, or multi-station use.

Advantages: High flexibility and adaptability to various scenarios.

Disadvantages: Generally has lower torque capacity than fixed bucking units.

3. Containerized Bucking Unit: The bucking unit, along with the hydraulic station, control system, toolbox, and other components, is integrated into a standard container to form a standalone "mobile operating unit." It is suitable for temporary field operations, offshore platforms, or unmanned bases. Advantages: Modular deployment, easy transportation, and quick commissioning.

Disadvantages: High initial investment and large footprint.

Classification by Functional Combination

1. Makeup-only Type

Supports only connection functionality and is suitable for pre-assembly of tools at the factory. Does not have disassembly functionality. Suitable for production lines and initial tool assembly.

2. Breakout-only Type

Supports only disassembly functionality and is primarily used for repair and maintenance. Suitable for repair shops or inspection of retired tools.

3. Makeup/Breakout Combination Type

The most common and practical type, capable of both threaded connection and disassembly, with bidirectional rotation capability and the highest adaptability.

Special Features: Bucking Unit

With technological advancements, some high-end bucking units are beginning to feature the following advanced features:

Automatic workpiece type recognition and loading of corresponding process parameters

Dual torque/angle control

Full-process data logging and cloud storage

Remote control and remote diagnostics

Automatic centering with vision-assisted positioning

These features primarily address the processing needs of high-precision, high-value workpieces, reflecting the trend toward intelligent and automated bucking units.

Conclusion

In summary, Bucking Units can be categorized into various types based on factors such as drive mode, control method, clamping style, mounting method, and functional combination. Each type offers unique application scenarios and technical advantages. When selecting a bucking unit, consider factors such as workload intensity, operating environment, tool type, quality standards, and budget. Choosing the most suitable model ensures connection quality while improving efficiency, reducing operational risks, and extending tool life.

Português

Português