What is a Bucking Unit?

Browse services

- Petroleum and Gas

- What are the advantages of using a Bucking Unit?

- Common Bucking Unit Operation Errors and How to Avoid Them?

- What are the safety checks before operating a Bucking Unit?

- Bucking Unit Safety Operating Procedures

- How to Use the Operator Panel to Control a Bucking Unit

- How to Calibrate a Bucking Unit?

- What preparations are needed before using the Bucking Unit?

- What is the operating procedure of the Bucking Unit?

- Common faults and troubleshooting methods during the use of Bucking Unit

- How should I replace worn parts of the Bucking Unit?

- How to maintain the electronic control system of the Bucking Unit?

- How does Bucking Unit handle oil leaks?

01 Aug

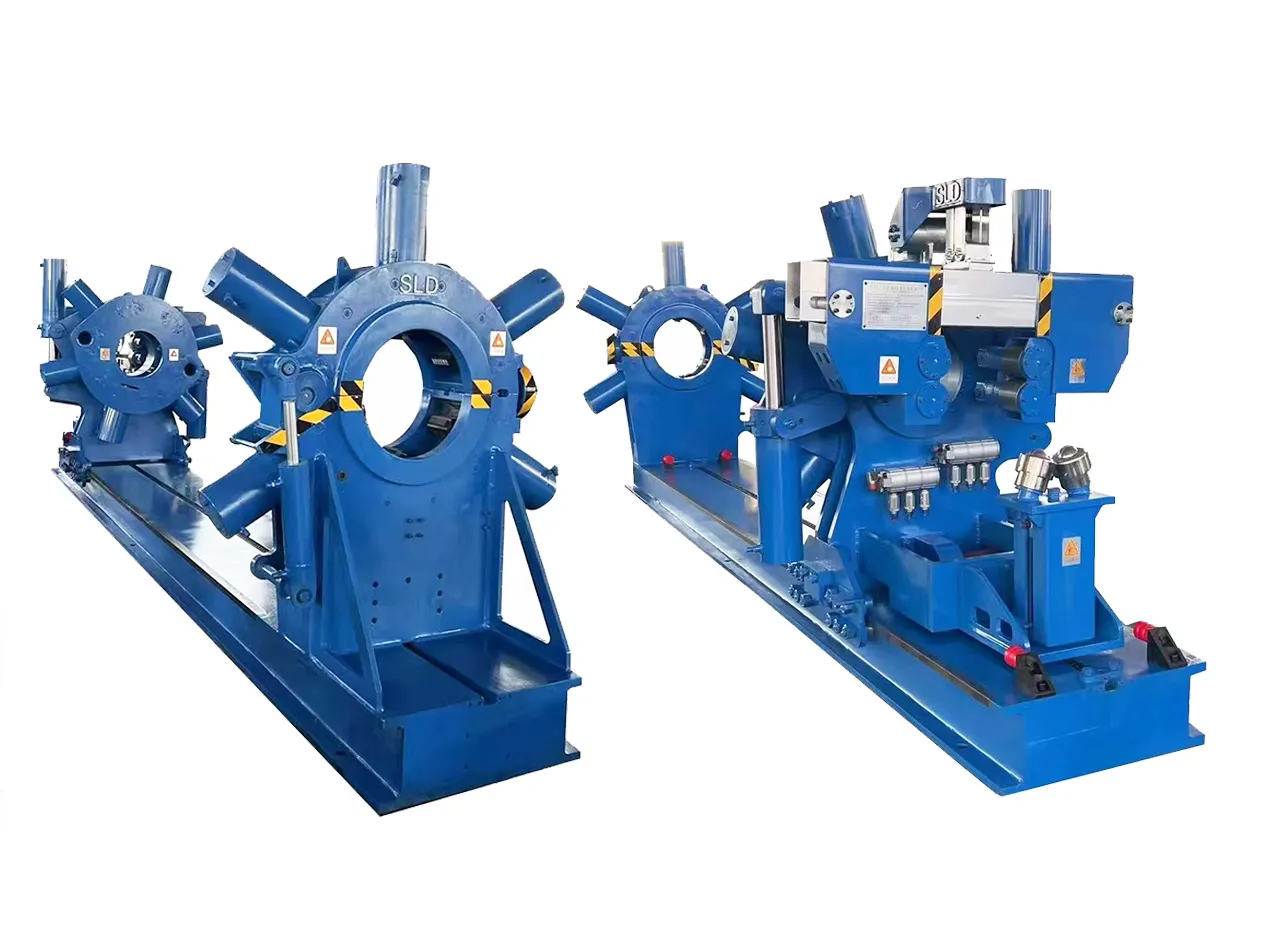

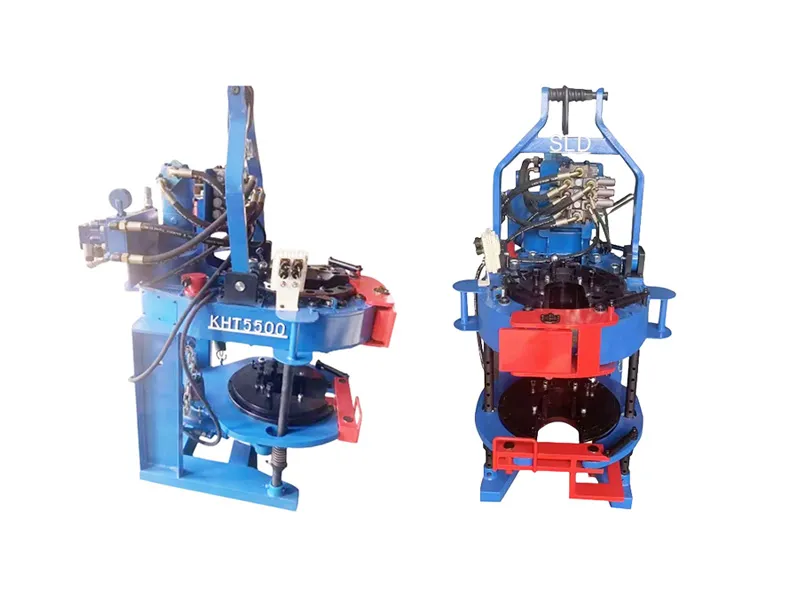

Bucking Units, also known as threaded connection breakout devices or hydraulic breakout machines, are specialized equipment used in the oil, gas, and other energy industries. They are primarily used for making and breaking threaded connections between tools and pipes. By controlling torque and rotational direction, they precisely clamp, rotate, and tighten/untighten tubular tools, ensuring reliable connection and sealing during downhole operations.

1. Core Function of the Bucking Unit

The Bucking Unit's primary function is to connect or disconnect two threaded metal components (such as drill pipe, joints, and tool connectors) using precisely controlled torque. This seemingly simple process demands extremely high precision and stability. Tools used in the oil and gas industry often withstand extreme conditions such as high pressure, high temperature, and high torque. Unreliable connections can lead to downhole accidents, tool damage, and even downtime.

Traditional manual connections or those using non-specialized equipment are prone to problems such as thread damage, insufficient torque, and poor sealing. The Bucking Unit addresses these industry pain points, providing a standardized, mechanized, and efficient solution.

2. Basic Components and Operating Principles

A bucking unit typically consists of the following key components:

Power System: Commonly hydraulically driven, but some utilize electric or pneumatic drives to provide the required torque.

Clamping System: Comprised of a fixed jaw (static jaw) and a movable jaw (dynamic jaw), these jaws clamp the tool ends, ensuring they do not slip or shift during operation.

Torque Control System: Enables precise torque setting and real-time monitoring, ensuring every connection is within specified standards.

Control Interface: Used to operate the device, set parameters, and read data. It can be button-based, touchscreen, or integrated with a PLC automation system.

Sensor and Data Acquisition Module: Records torque curves, angles, and other data for each connection for quality control and traceability.

During operation, the device clamps the tool ends, and the dynamic jaw begins rotating, applying torque via a hydraulic or electric system. Rotation automatically stops when the set torque value is reached, completing the connection or disassembly process.

3. Application Scenarios

The Bucking Unit is widely used in the following operational scenarios:

Oil and gas industry: connecting downhole components such as drill tools, casing, logging tools, and while-drilling tools.

Tool manufacturing plants: pre-connecting or testing tool connection performance on the production line.

Repair and rework shops: disassembling or reconnecting damaged or used tools.

Quality inspection departments: verifying that tool thread connections meet the designed torque and angle standards.

In these scenarios, the Bucking Unit's high torque control, high repeatability, and data traceability ensure secure tool connections and efficient operations.

4. Advantages and Features

Compared to traditional methods, the Bucking Unit offers the following advantages:

High-precision torque control: Precisely controls torque within specified tolerances, preventing over- or under-tightening.

High operational efficiency: Fully mechanized operation significantly increases production and maintenance speed.

Reduced manual risk: Reduces manual intervention and reduces the risk of operator injury.

Strong thread protection: Constant torque output prevents damage to threaded and sealing surfaces. Recordability and Traceability: Modern equipment can store torque and angle data for each connection, facilitating quality management.

Adaptability: It can accommodate a wide range of tool specifications, supporting different diameters and lengths.

5. Why are bucking units indispensable in the energy industry?

With the continuous development of the energy industry, downhole tools are becoming increasingly complex, requiring increasingly precise connections. Traditional manual methods are no longer able to meet the demands for safe, efficient, and standardized operations. In this context, bucking units have become indispensable.

Especially in high-pressure, high-temperature, and challenging well conditions, the stability of threaded connections is directly related to operational safety. A failed connection can have devastating consequences. Therefore, the use of bucking units plays an irreplaceable role in ensuring project quality and safety, both at the production end and on the job site.

6. Future Development Trends

With technological advancements, modern bucking units are developing in the following directions:

Intelligence: Introducing automatic recognition, automatic control, and remote operation features to achieve a higher degree of automation.

Data Integration: Connecting with site management systems enables data collection and visualization throughout the entire process.

Multifunctionality: A single device can handle a wider range of tool types and sizes. Lightweight and modular: It facilitates rapid deployment and disassembly between different sites.

Conclusion

In short, the Bucking Unit is a vital piece of equipment connecting modern production and operations in the oil and gas industry. By precisely controlling torque, angle, and connection quality, it significantly improves operational efficiency and safety, making it a core tool in energy equipment manufacturing, maintenance, and field operations. As the industry's demands for equipment reliability and operational efficiency continue to rise, the Bucking Unit's application will become increasingly widespread, and its technology will continue to evolve.

Português

Português