What are the main maintenance items of Bucking Unit?

Browse services

- Petroleum and Gas

- What are the advantages of using a Bucking Unit?

- Common Bucking Unit Operation Errors and How to Avoid Them?

- What are the safety checks before operating a Bucking Unit?

- Bucking Unit Safety Operating Procedures

- How to Use the Operator Panel to Control a Bucking Unit

- How to Calibrate a Bucking Unit?

- What preparations are needed before using the Bucking Unit?

- What is the operating procedure of the Bucking Unit?

- Common faults and troubleshooting methods during the use of Bucking Unit

- How should I replace worn parts of the Bucking Unit?

- How to maintain the electronic control system of the Bucking Unit?

- How does Bucking Unit handle oil leaks?

06 Aug

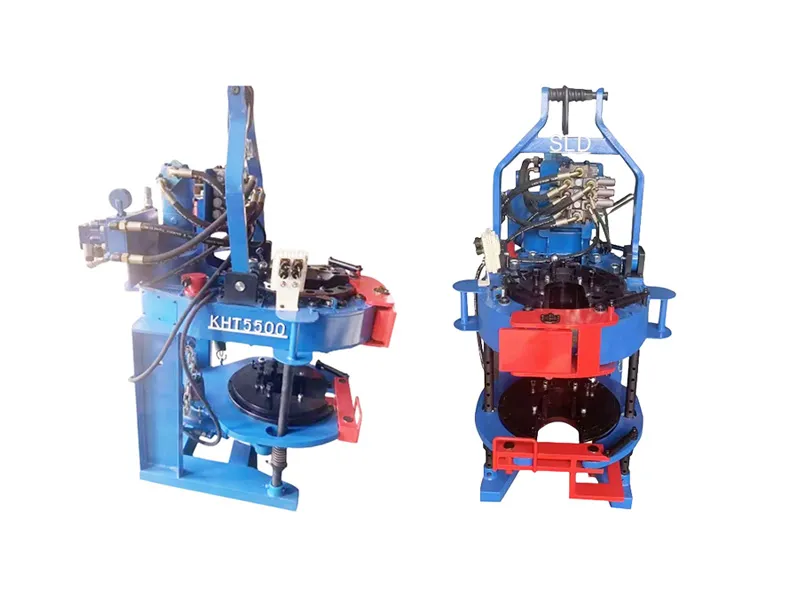

Bucking units (joining units) are essential equipment used in the oil and gas industry to connect and disconnect drill pipe, tubing, casing, and other tools. They operate frequently, under heavy loads, and often operate in complex and changing field environments. To ensure continued efficient operation and connection accuracy, systematic and periodic maintenance is essential. Bucking unit maintenance involves multiple aspects, including the hydraulic system, electronic control system, mechanical structure, safety devices, and sensor systems. Systematic and standardized maintenance directly impacts equipment lifespan, operational efficiency, and safety.

The following is a detailed description of the main maintenance items for a bucking unit:

1. Hydraulic System Maintenance

The hydraulic system is the core component of the bucking unit for power output and control operations. Any failure or contamination can lead to unstable operation or complete failure. Therefore, hydraulic system maintenance is one of the most critical aspects.

1. Hydraulic Oil Replacement and Monitoring

Hydraulic oil is the system's working medium. Over time, it can deteriorate due to factors such as temperature fluctuations, contamination, and moisture ingress, affecting system response speed and accuracy. Regularly inspect the oil quality and replace it promptly if discoloration, foaming, or abnormal viscosity are observed. 2. Hydraulic Oil Level Check

The oil tank level must remain within the normal range. If the oil level drops, locate the leak, refill the oil, and remove any air.

3. Clean or Replace the Oil Filter

The filter is a key component that prevents particulate matter from entering the system. It should be replaced at the prescribed interval to prevent blockage, abnormal system pressure, or component damage.

4. Check Hydraulic Lines and Connectors

Hydraulic hoses and connectors are susceptible to aging or loosening due to prolonged exposure to high pressure. Regularly check for leaks, damage, or loose connections to ensure proper system sealing.

5. Hydraulic Cylinder and Valve Manifold Maintenance

Inspect the hydraulic cylinder for unusual noises, sluggish movement, or internal leakage. Check the valve manifold for proper operation and any signs of sticking or poor response. Clean or replace seals if necessary.

2. Electronic Control System Maintenance

The electronic control system is responsible for drive control, signal acquisition, torque and angle management, and is the core of intelligent operation. Its stability directly impacts operational safety and connection quality.

1. Control Cabinet Interior Cleaning

Regularly inspect the control cabinet for dust accumulation, loose connectors, and damaged cables. Dust can cause short circuits or overheating, shortening system life.

2. Cable and Connector Inspection

Verify that cables are not broken or peeling, and that connectors are in good contact. Be careful to prevent poor contact caused by vibration or oil.

3. Control Panel and Touchscreen Testing

Test button responsiveness and touch accuracy. If there are operational delays or a black screen, check the control board power supply and display driver.

4. PLC and Program System Testing

Periodically verify the functionality of the programmable logic controller, checking signal input and output for normal operation and any unexpected breakpoints in the program.

5. Torque and Angle Control System Calibration

Calibrate the torque sensor and angle encoder to ensure accurate data acquisition and avoid overtightening or loosening connections.

3. Mechanical Structure Maintenance

The Bucking Unit consists of a base, mainframe, jaw system, and rotation mechanism. The stability of these mechanical components determines overall rigidity and operational accuracy.

1. Jaw System Inspection

The jaws are the core components that directly contact and clamp the workpiece. Check the jaw pads for wear, cracks, gaps, or deformation, and replace if necessary.

2. Guide Rail and Slide Lubrication

All sliding components, such as guide rails and slides, must be well lubricated. Dryness can lead to sluggish movement or abnormal noise, increased wear, and even seizure.

3. Spindle and Coupling Inspection

The spindle system should be inspected for smooth operation and any eccentricity, runout, or abnormal vibration. The coupling should be inspected for tightness of the connecting bolts.

4. Resetting Fasteners and Connectors

Periodically inspect all bolts, nuts, and pins for looseness, especially critical parts subject to alternating loads. These should be re-tightened regularly.

4. Safety Device Maintenance

The Bucking Unit operates under high torque and pressure, and any minor malfunction could potentially lead to a safety incident. The integrity of safety devices is the last line of defense for protecting equipment and personnel.

1. Emergency Stop Button Test

Periodically press the emergency stop button to test the response speed and immediate system shutdown to prevent failure at critical moments.

2. Limit and Travel Protection Check

Check that all limit switches and sensors are functioning properly to ensure that the clamping/unclamping action does not exceed the travel limit.

3. Over-Torque Protection Function Verification

Set appropriate torque alarm and power-off points, and regularly test that the protective devices operate accurately when the torque exceeds the limit.

4. Guard and Protective Structure Inspection

Check that the guard is intact and securely installed to ensure that the operator cannot easily access hazardous areas.

5. Software System and Record Maintenance

Modern bucking units are typically equipped with an operation record system and equipment self-diagnostic programs to support ongoing management and troubleshooting.

1. Operation Data Backup

Regularly export and save connected operation history data, alarm logs, and equipment parameters to prevent data loss.

2. System Software Update

Upgrade the software version as recommended by the equipment manufacturer to ensure system stability and compatibility. 3. Fault Self-Diagnosis Function Test

Test the system's ability to automatically identify common faults and generate alarms, improving maintenance response speed.

Conclusion

Bucking unit maintenance should not be limited to fault repair; it should also prioritize preventive and systematic management. The above maintenance items should be incorporated into the company's equipment management system, organized and implemented on a regular basis, with a comprehensive maintenance record and accountability system. Strictly adhering to the maintenance plan not only extends equipment life and improves operational efficiency, but also effectively prevents safety incidents and ensures the stability and reliability of the overall operating system. In high-intensity operating environments, standardized maintenance management is not only a technical requirement but also a cost-control and safety measure.

Português

Português